Productivity Pain Points

WHAT TYPE OF ORGANIZATIONS NEED THESE SERVICES? LOW-VOLUME HIGH MIX INNOVATIVE TEAMS—> YES, REPETITIVE NON-INNOVATIVE —>NO

Here’s a breakdown of productivity pain points at different organizational scales, starting with a large organization with teams distributed across different sites and projects before completing at the level of individual engineers.

Multiple business units

Analysis software (used to predict phenomena and performance) is underutilized, for several reasons:

Training requirements are onerous for the scope of the task involved

Hardware requirements and licensing requirements create extra constraints on learning how to use the software

Understanding what questions the software is good at answering creates waste and frustration

There is no good software to analyze what the team needs analyzed

Fragmentation: multiple pieces of software are required to perform a full analysis and the expertise to connect them doesn’t exist or

Balance of simulation versus experiment is over compensated towards experiments which can increase the cost of a decision point.

Design software (CAD) can be difficult to drive adoption, even if simple to use.

Research work is most likely to pull on a number of different disciplines to support novel experiments. Items needed include:

Custom components

Novel detection methods

New fixturing components

Use of existing manufacturing equipment, components

Design iterations are challenging at all stages

Goldilocks design changes are hard to find. They happen not so slowly that the change will ripple through with potential unintended consequences, and not too fast that everyone assumes the design will change so quickly that they should invest any time into its current state

Difficulty creating “forks” of a hardware design to understand how a change will ripple through so marginal designs get frozen. This pushes engineers to “get it right” in the design phase if they can’t afford enough parts for experimentation

Work is often under documented, for example:

specifications are listed but initial design constraints are not populated. In the long term, manufacturing teams know what works, but have a harder time understand how to make improvements (costs, touch time, etc.) that don’t have long-term adverse consequences. This affects how manufacturing teams address process inefficiencies, etc. as they work to reduce costs and improve margins

Some organizations hinder sharing of information because they are incentivized to keep certain information “trade secret”, which is painful

Repeating mistakes that are well known in larger org, but may be out of technical knowledge base for smaller, disjointed teams

Duplicate work performed within an org by separate teams resulted in double the labor spend, and increased costs based on fewer common parts

Common method of solving: Assigning “specialists” that are responsible for processing all of a certain class of design or experimental work results in the formation of queues that can inhibit total organization efficiency at the expense of subject area efficiency

New product introduction pain points

Manufacturing design work is over accelerated (fixturing, etc) after customer validation of a new product if the customer is facing a finite market window. This results in higher than necessary spend, and is also a problem if engineering teams don’t design to use existing parts or retrofit existing parts.

Manufacturing space can be over consumed by new component manufacture

Manufacturing engineering pain points

Manufacturing engineering has to steal design support from product development teams in order to research, development and verify manufacturing improvements.

specifications are listed but initial design constraints are not populated. In the long term, manufacturing teams know what works, but have a harder time understand how to make improvements (costs, touch time, etc.) that don’t have long-term adverse consequences. This affects how manufacturing teams address process inefficiencies, etc. as they work to reduce costs and improve margins

Often, you end up with super-technologists who need to keep a running history of lessons learned, who knows what in the company, knows what people are doing at a low level of the organization, etc.

Business unit engineering teams

Description: Smaller team with resources, but can have gaps in expertise because of the reduced staffing compared to larger groups of engineers.

Project resource competition

Individual Engineers

The abacus problem —> The process of computation and analysis is a barrier to solving problems. Engineers are good at understanding complex, real world boundary conditions, customer expectations, etc.

NEED TO SOLVE A CLASS OF PROBLEM —> COMBINATORIAL COMPLEX ASSEMBLIES WITH SPEC’ED PERFORMANCE

We surveyed optical engineers about their experience using commercially available optical design software. There were asked if they agreed of disagreed with the statements describing the software they use.

A need for speed

The data show the most significant complaint for commercial software is the speed of generating solutions. While most attributes of commercial software were viewed positively, the resounding consensus opinion was that existing software is too find solutions.

Solution speed has a direct impact on an engineer’s day: time waiting for the software to find a solution is time an engineer needs to fill with another task. Additionally, engineering requires multiple iterations of design to understand trade-offs. So the disruption of waiting for a solution is compounded by the number of runs the engineer needs to perform.

Design library

Engineers liked using a design library so they didn’t need to generate high-level concepts themselves

Robust & efficient

Needs to be efficient

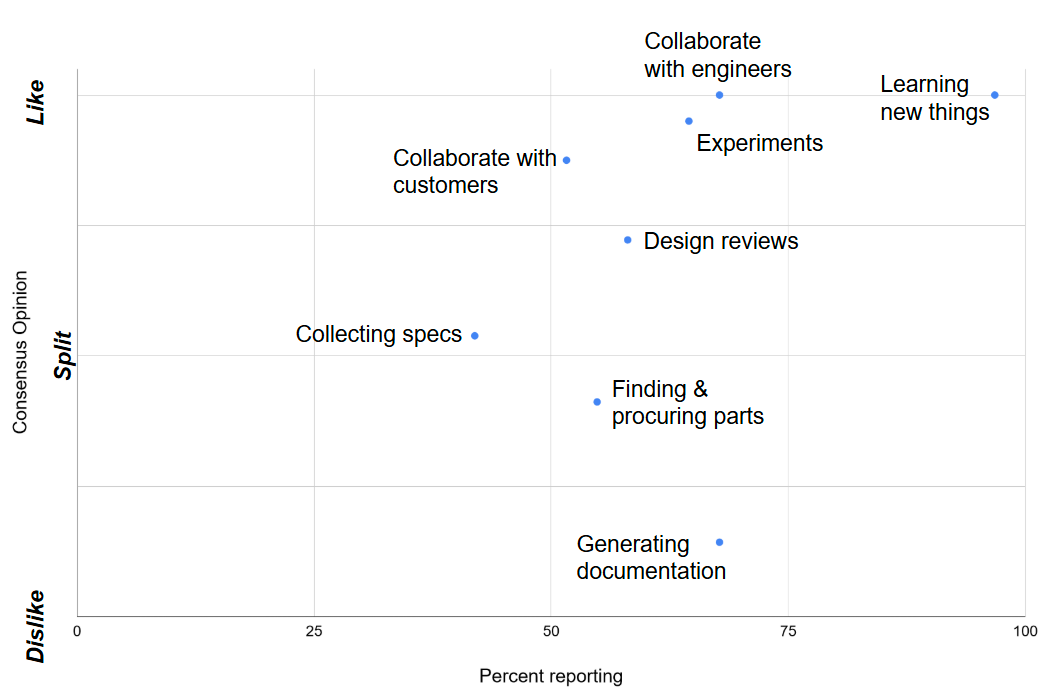

What engineers like and don’t like

Engage with others, learn new things, NOT individual work that’s fairly rote.